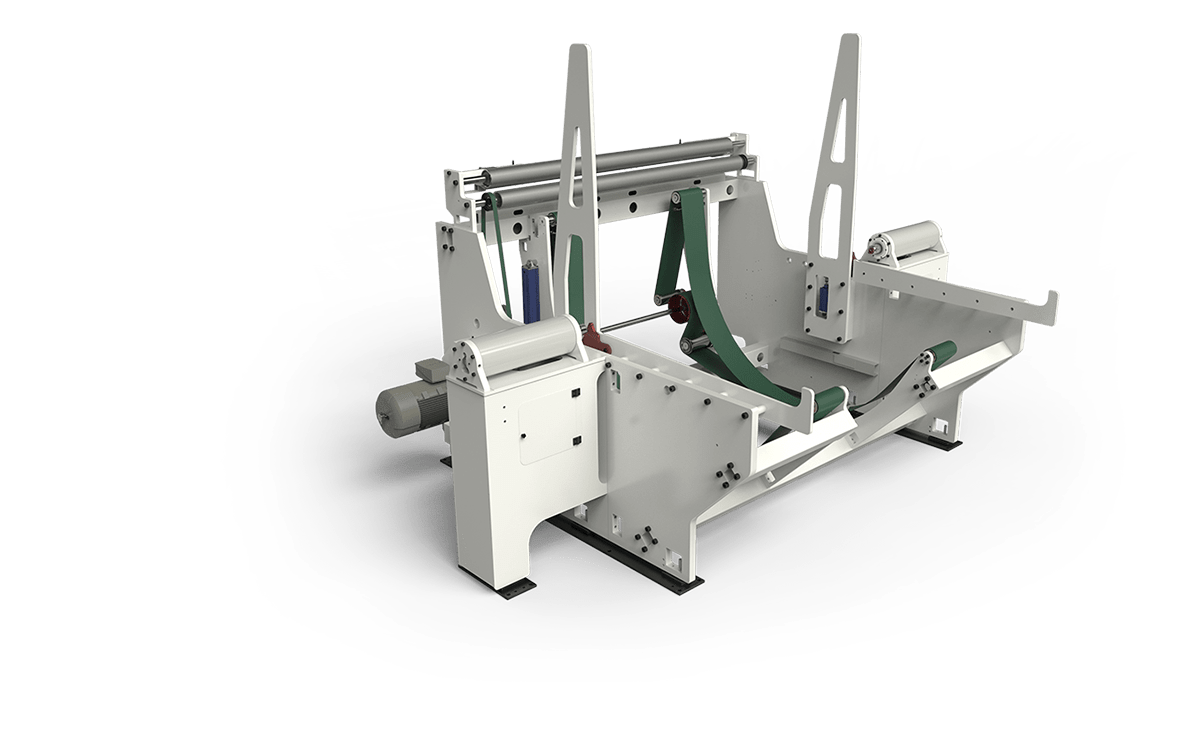

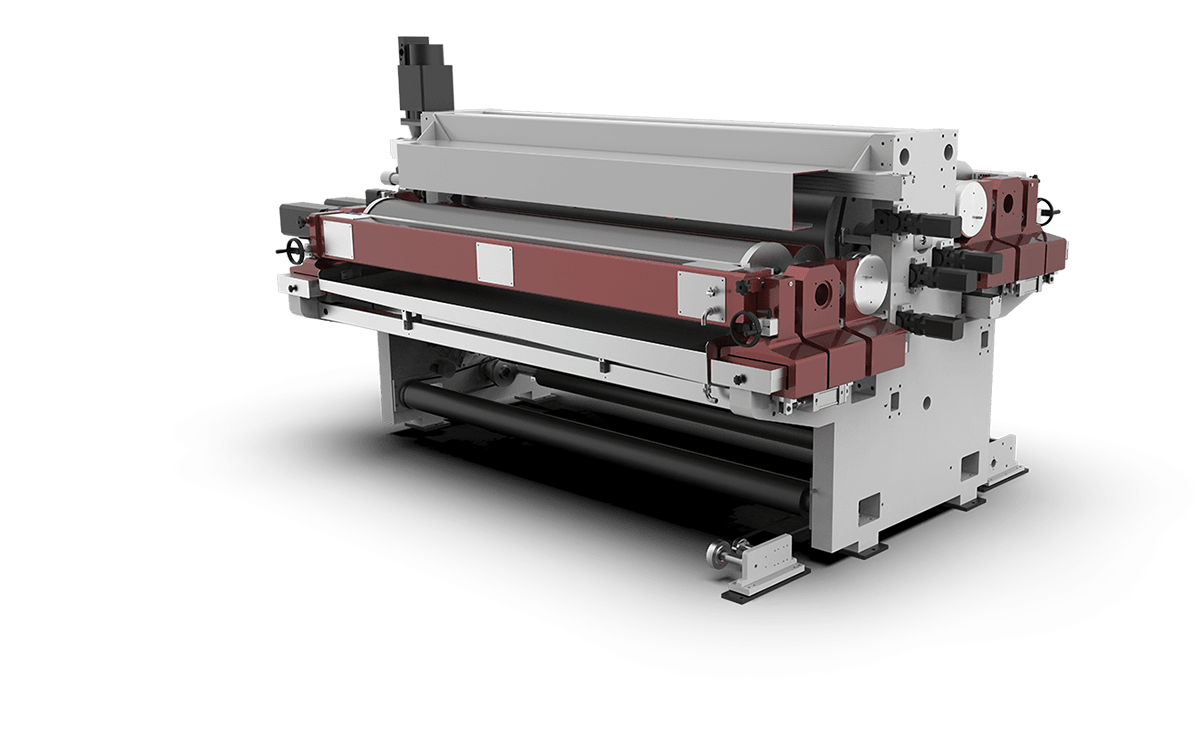

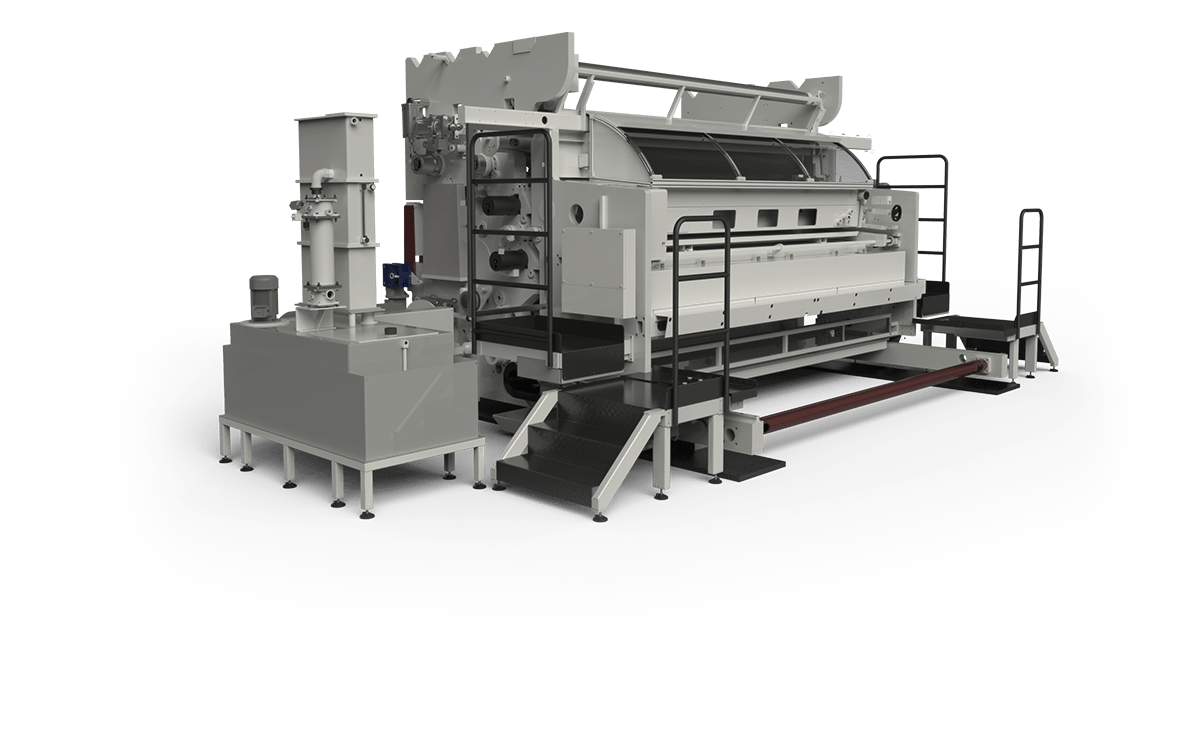

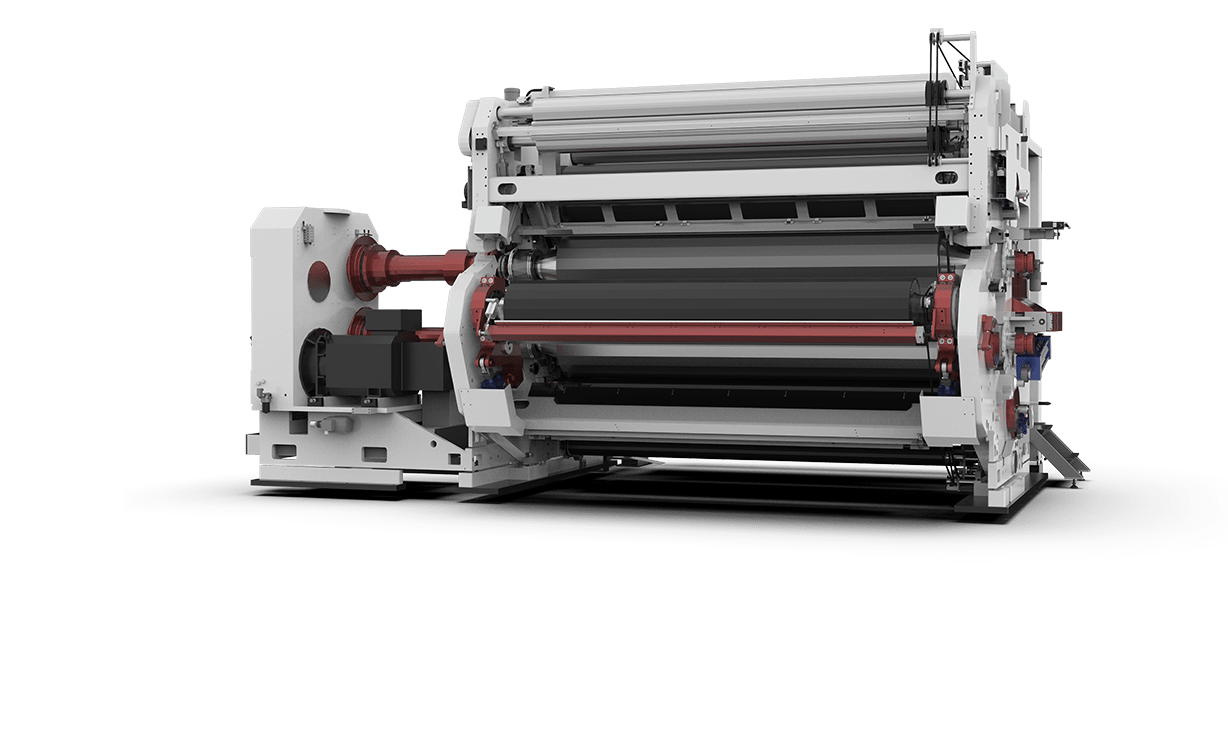

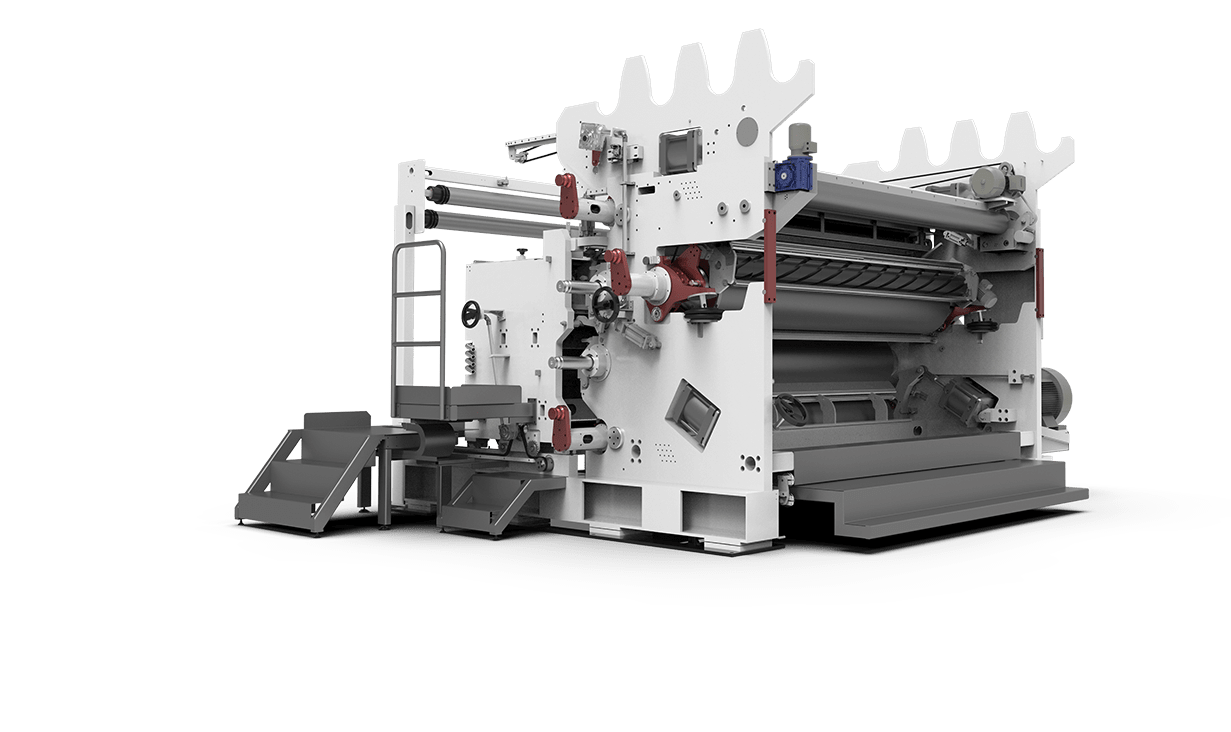

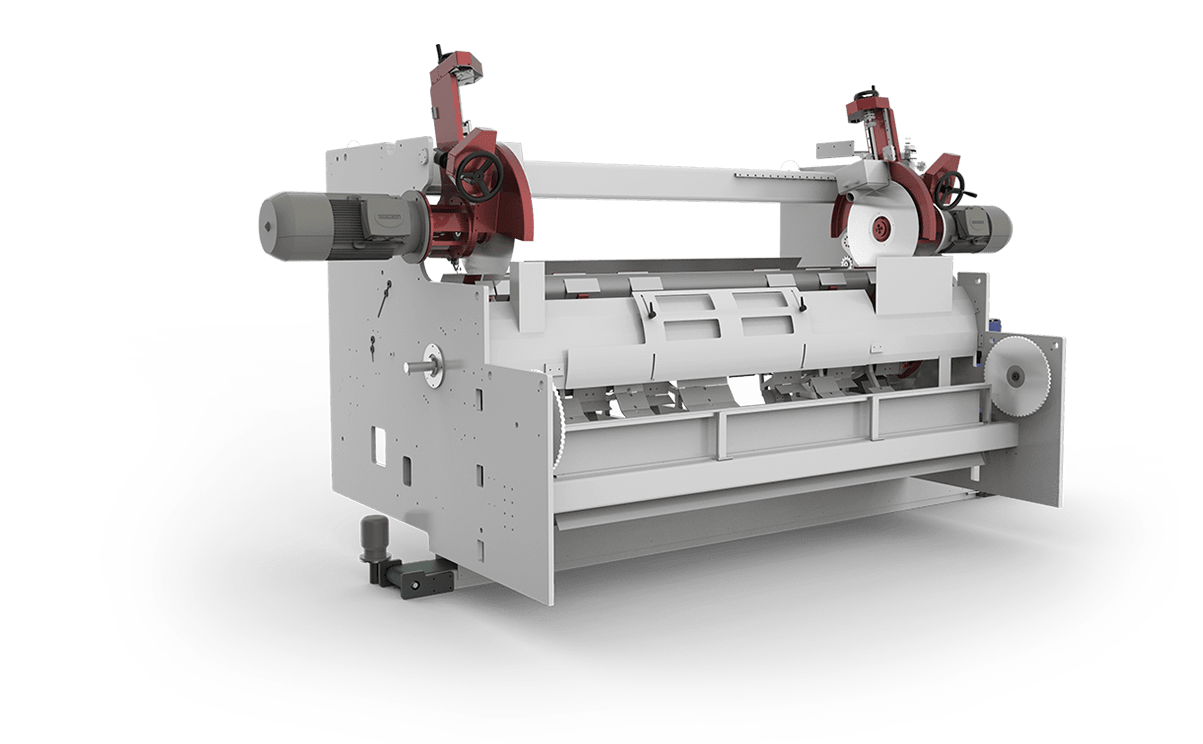

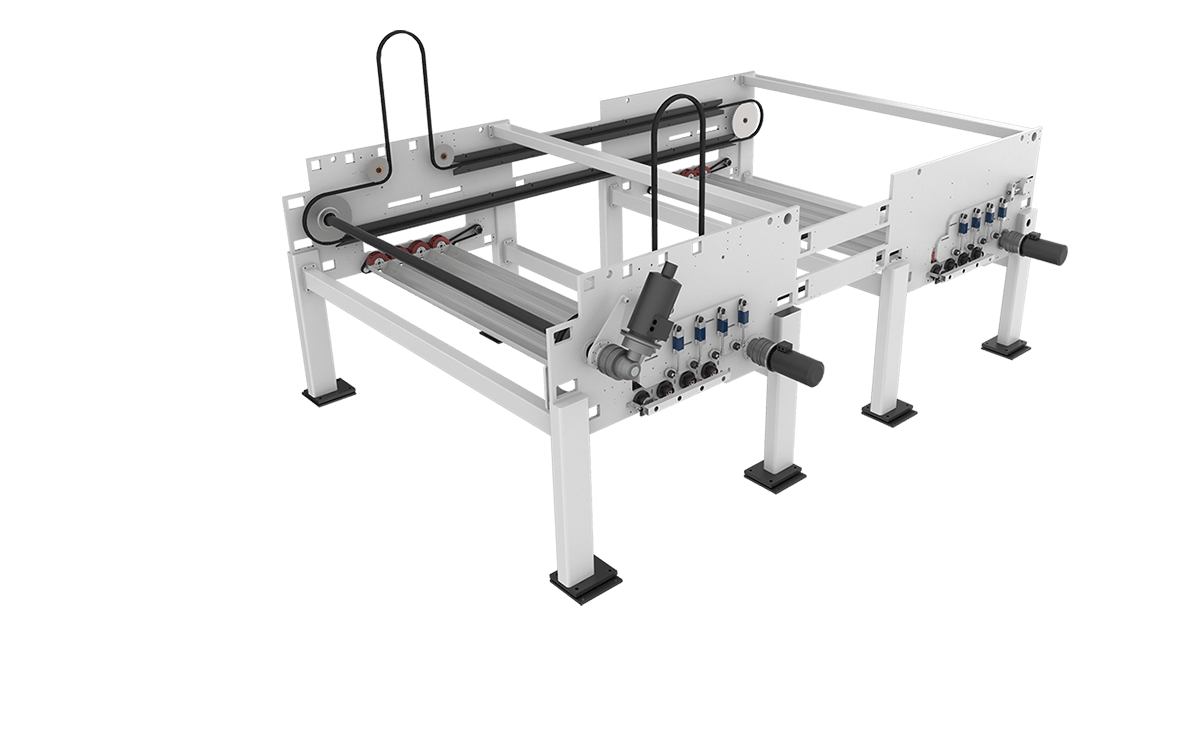

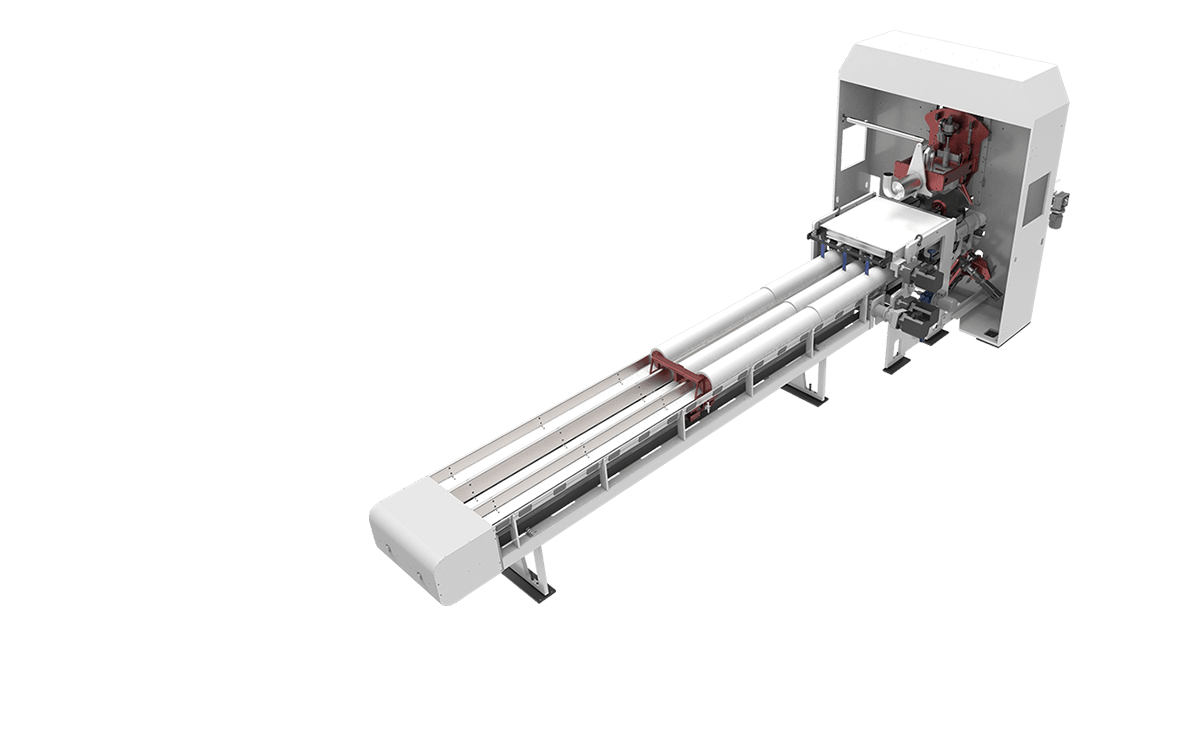

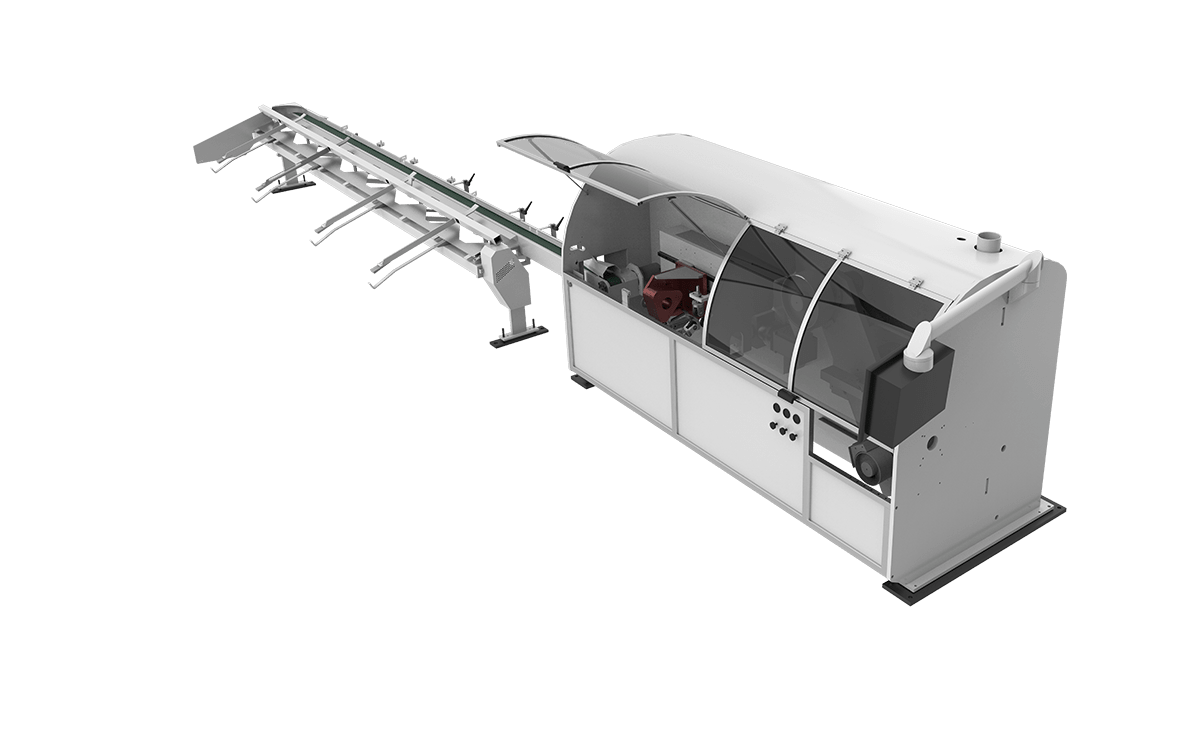

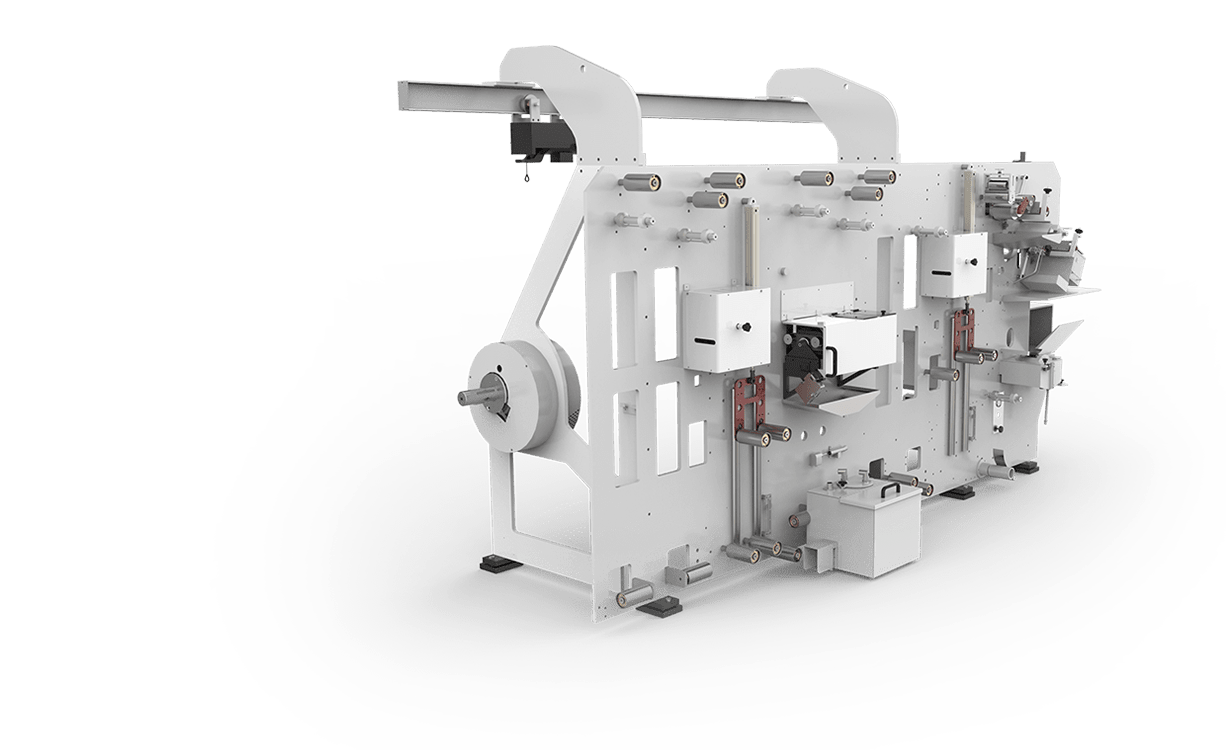

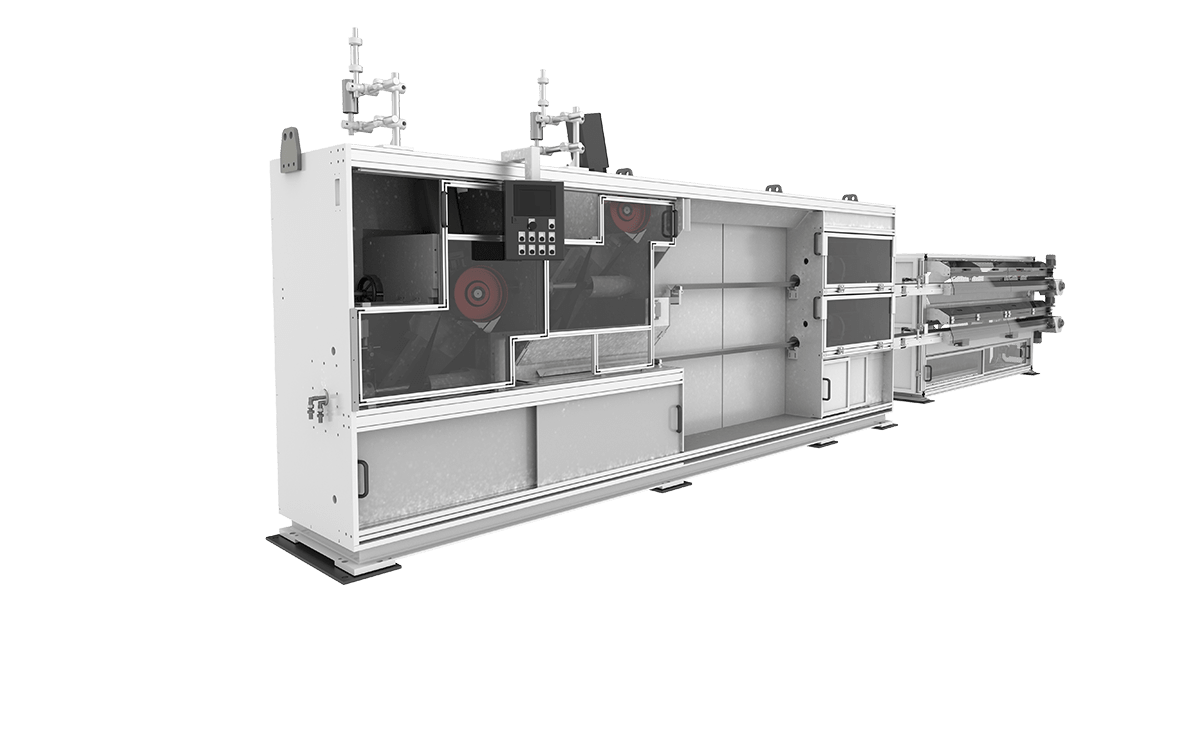

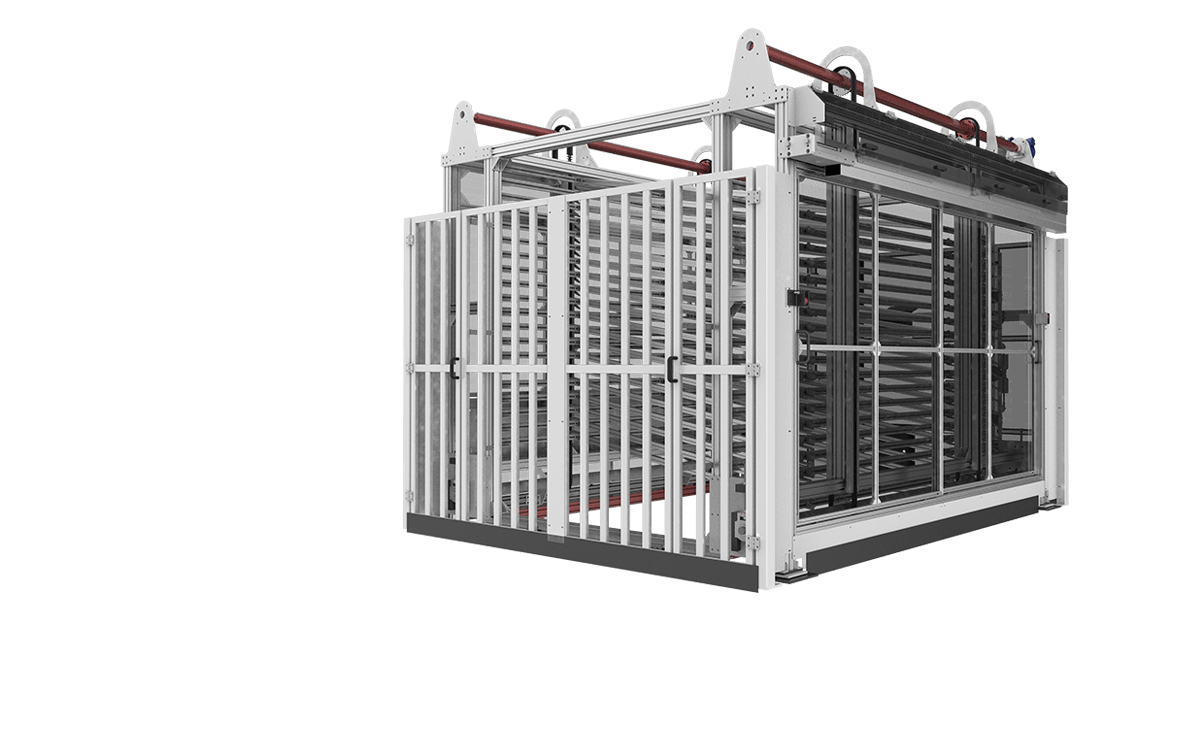

Consumer lines

Futura’s Consumer lines are designed to respond to the demands of a market segment which expects a specific standard of innovation and finished product quality. Futura lines guarantee tangible competitive advantages in terms of flexibility, safety, productivity and finished product quality. Ease of use and maintenance not only mean reduced learning curves for personnel but also shorter time getting lines up to speed. Naturally all lines can be configured according to specific requirements.

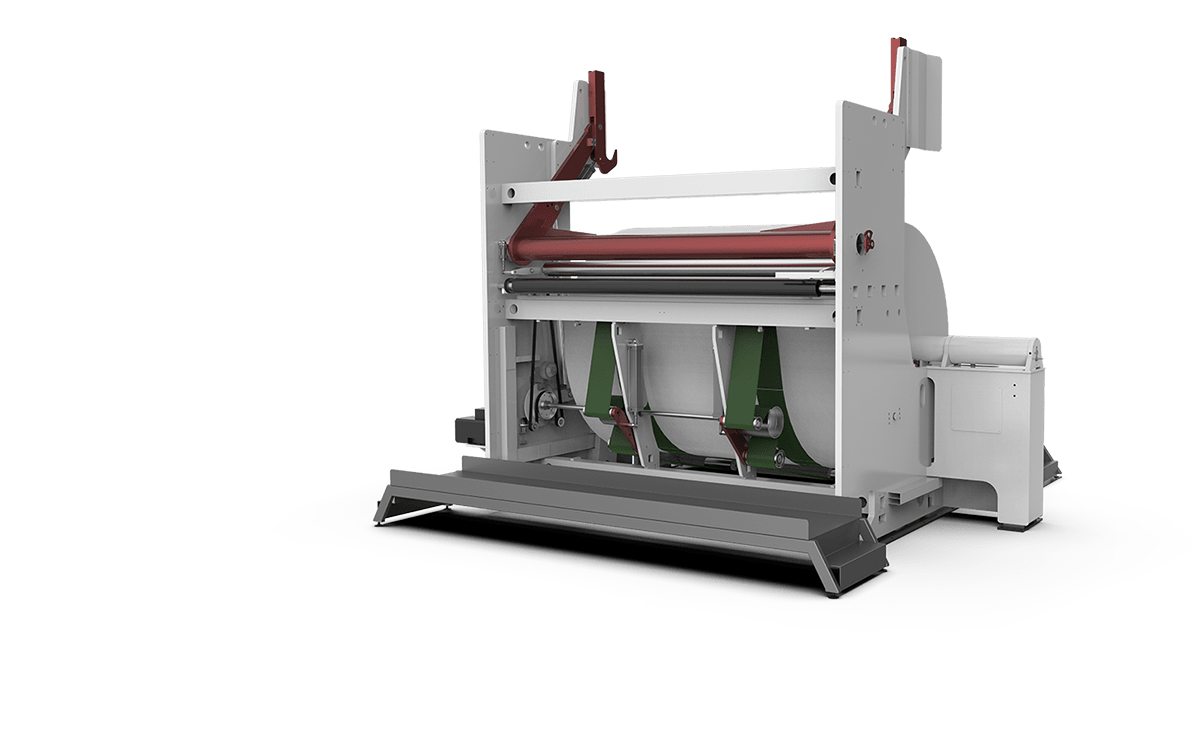

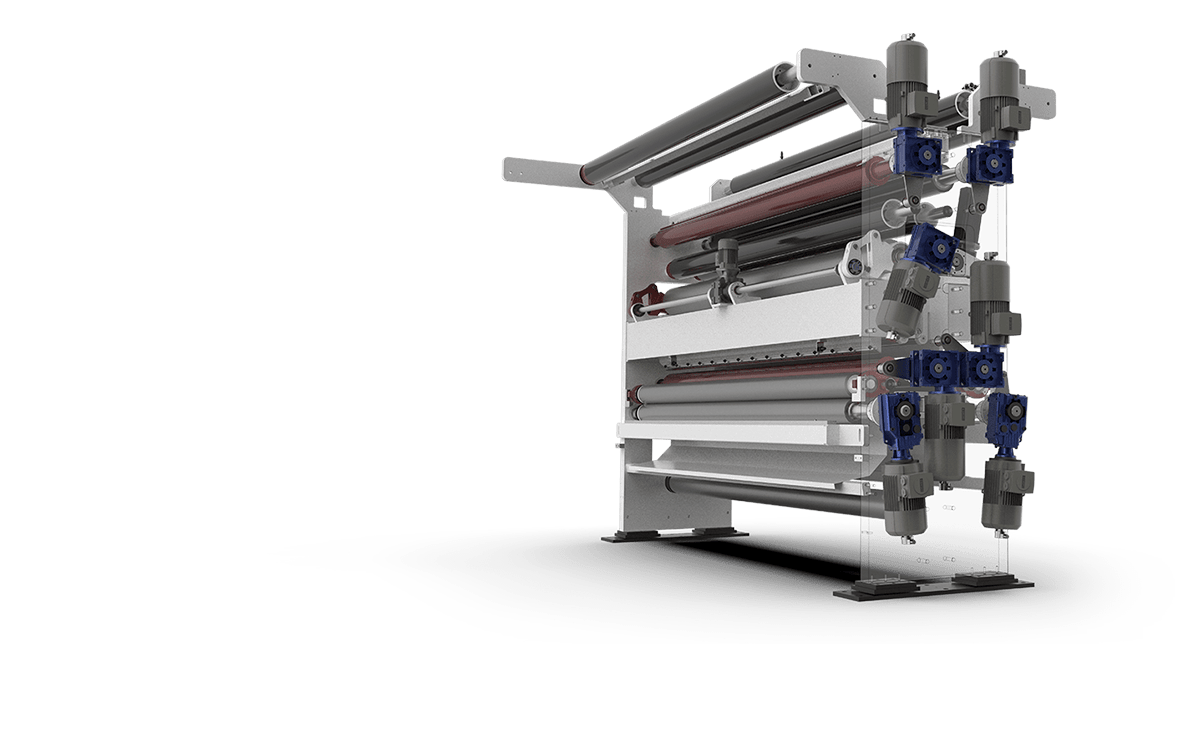

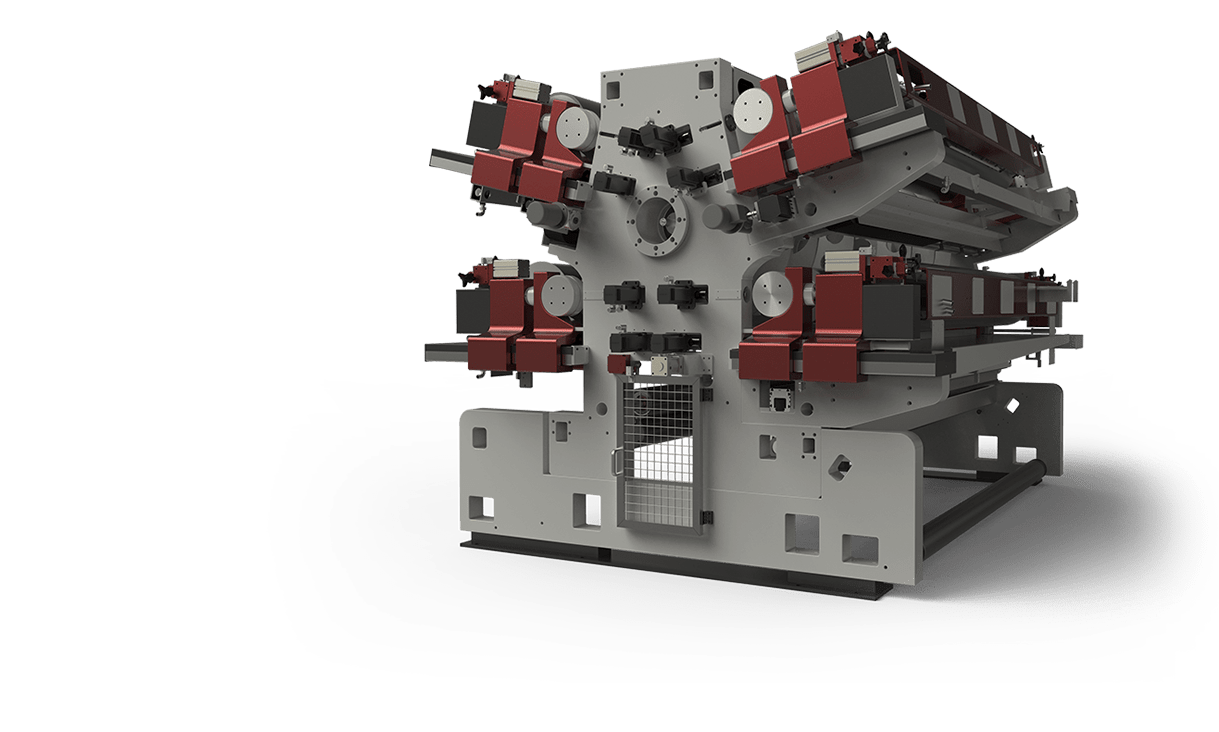

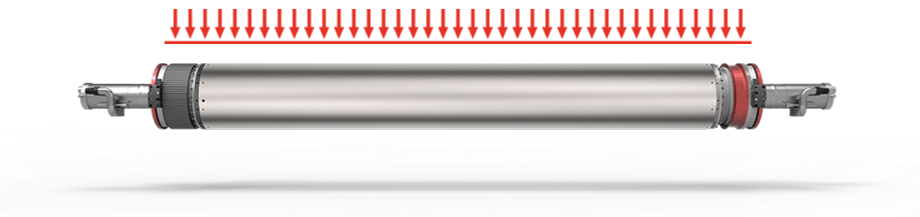

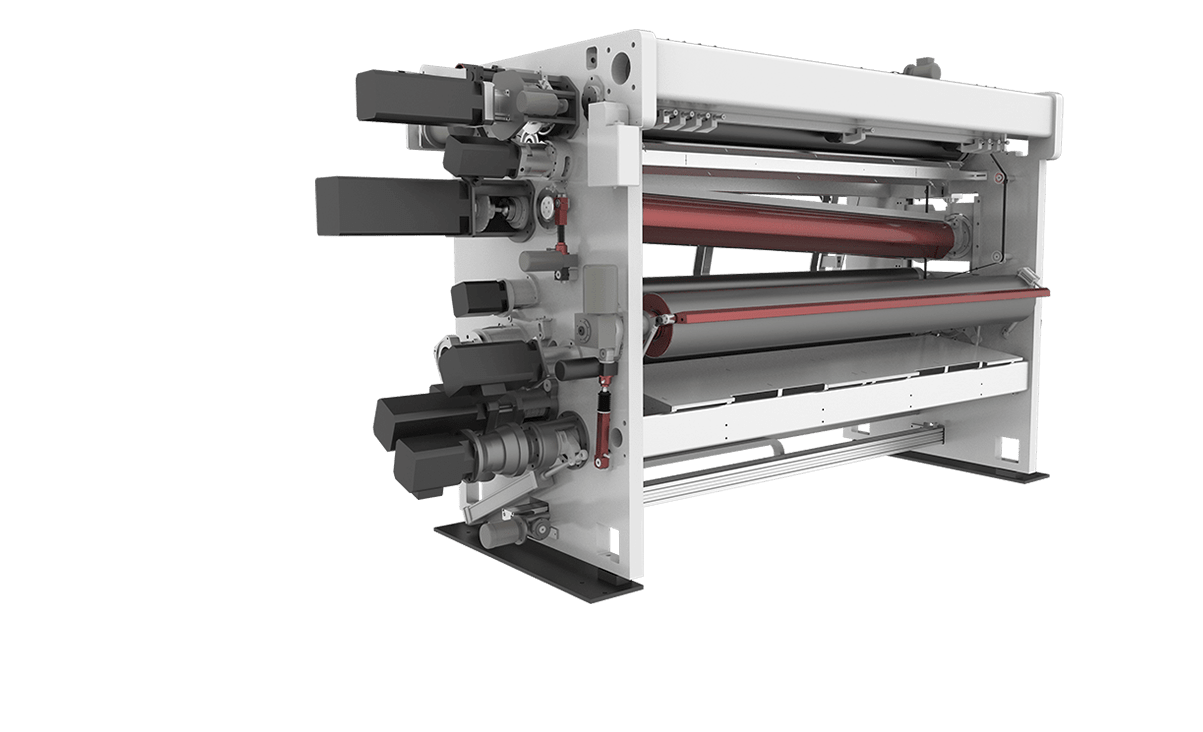

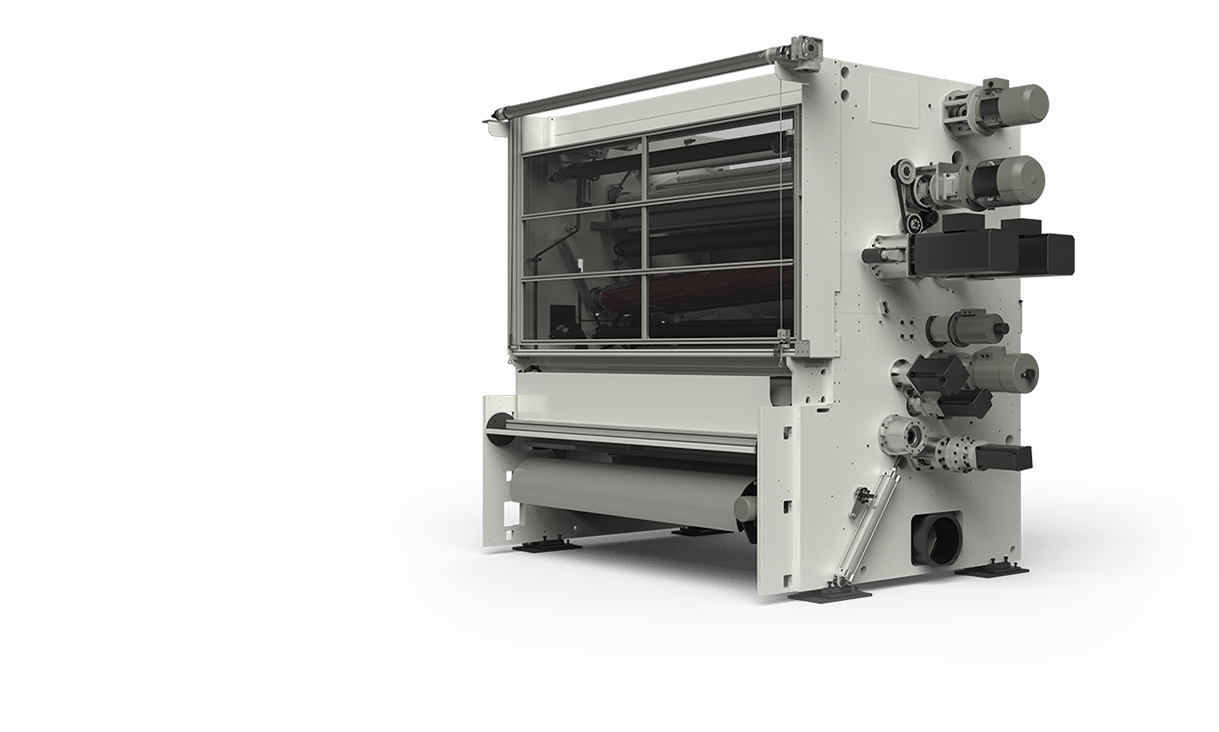

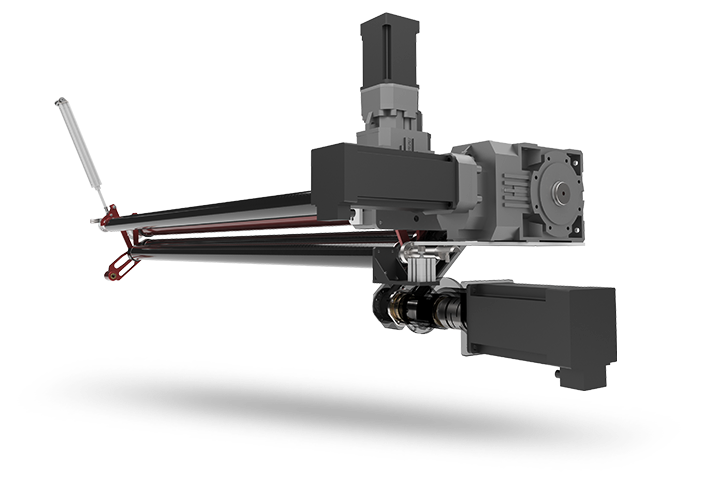

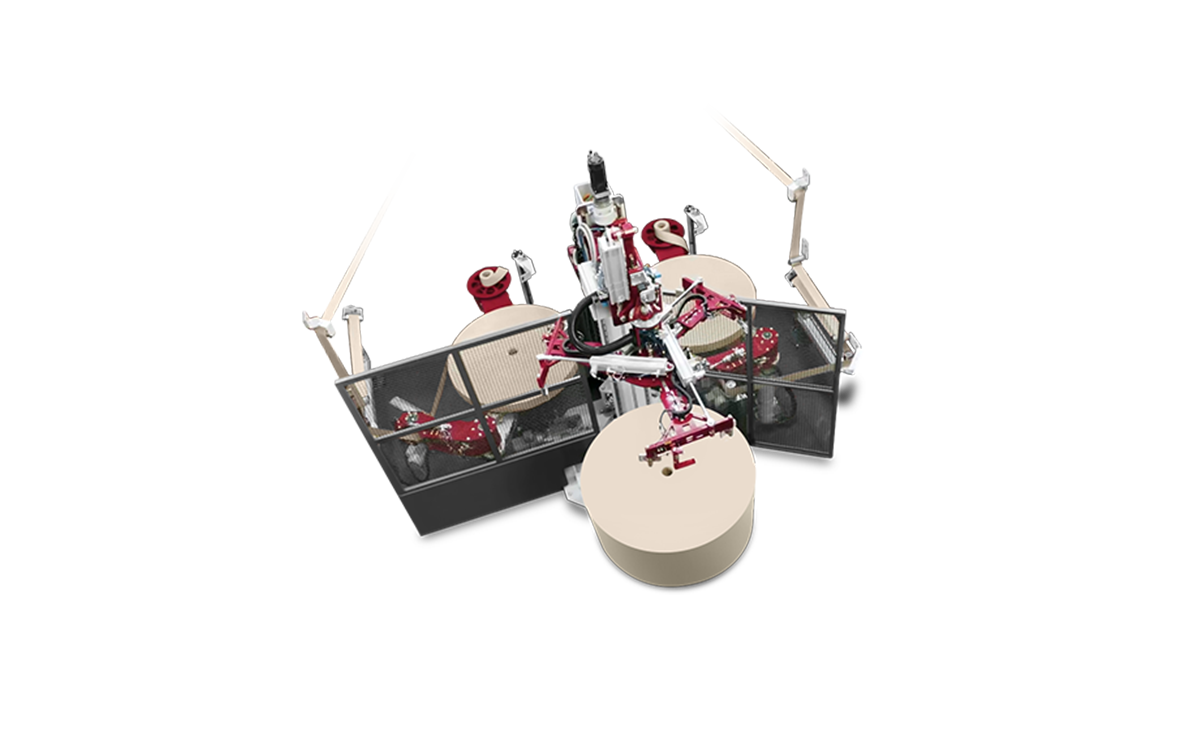

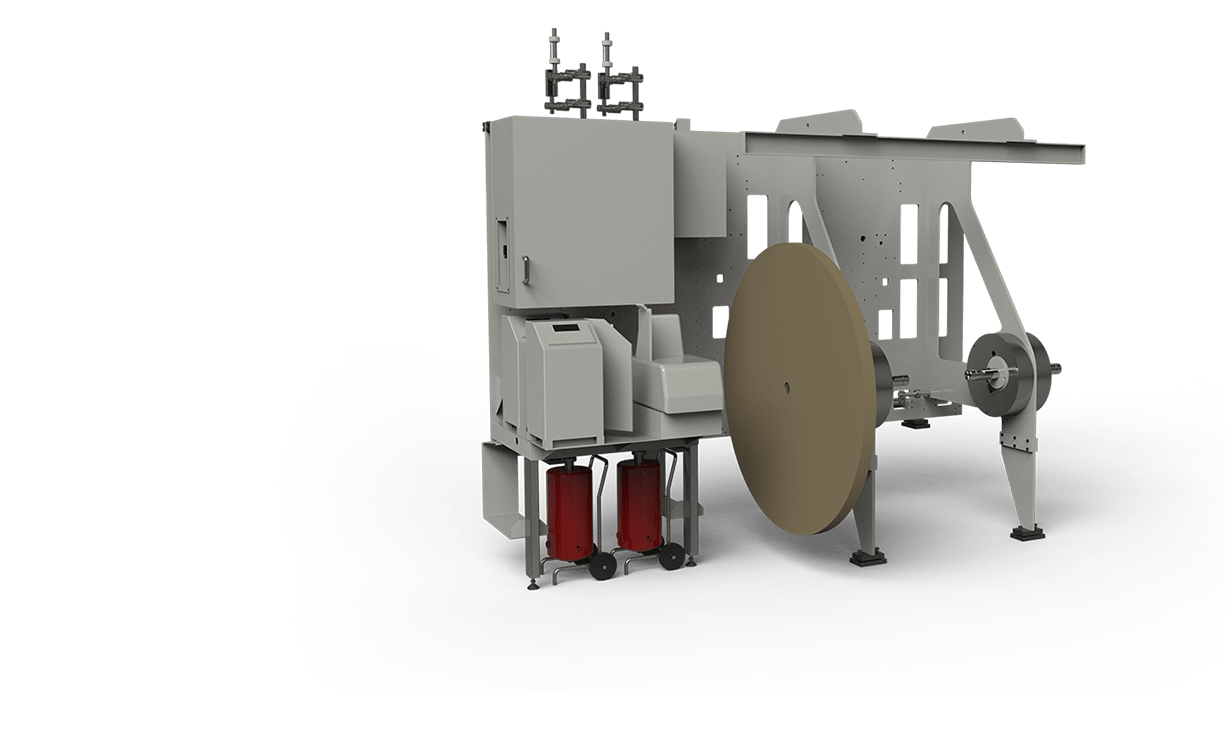

ANDROMEDA SYSTEM

Andromeda, which guarantees the best performance on the market,

embodies the future of converting. Today.

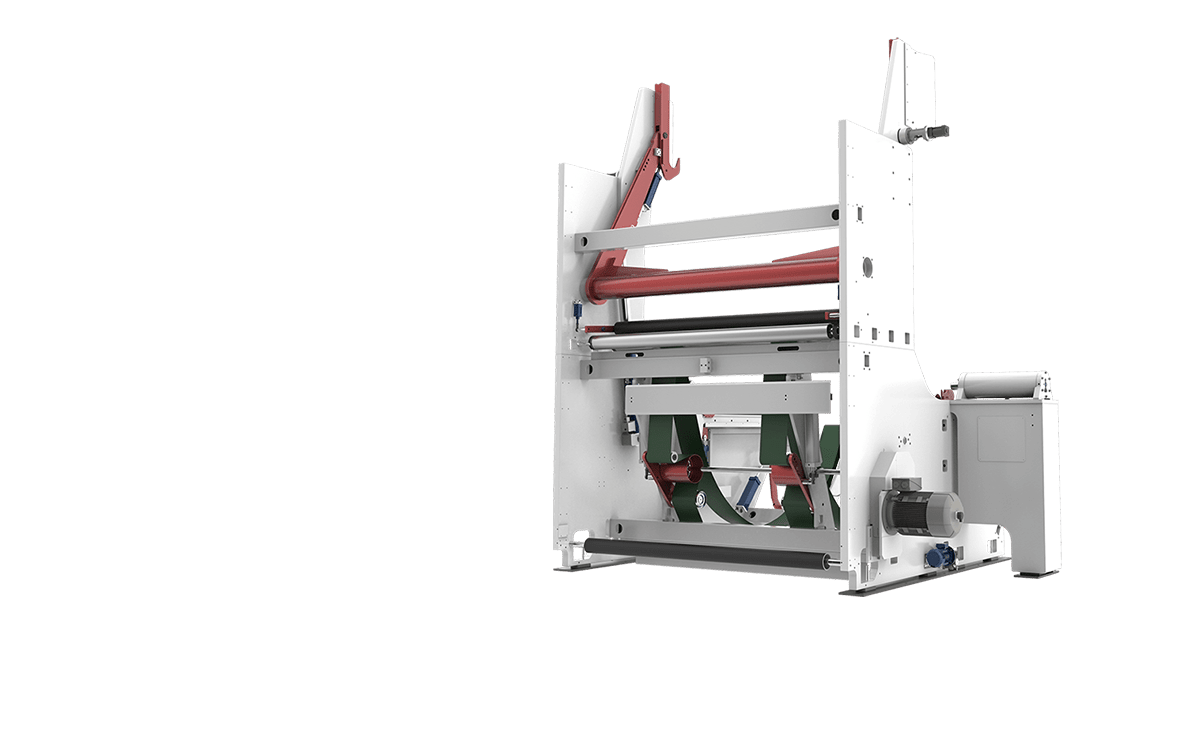

Suitable for installation on any Consumer line, it optimises a line’s performance in terms of automation,

process control and safety.